Knowledge Hub

Welcome to Matik’s Knowledge Hub

We are excited to introduce you to our knowledge hub, a one-stop shop for information about our premier equipment and how it can help your business increase profits and new opportunities. Our knowledge hub features case studies, videos and articles that showcase how companies in a variety of industries are using our equipment to improve their efficiency, productivity, and revenue.

Here are some of the things you can find in our knowledge hub:

- Case studies: Learn how other businesses have used our equipment to improve their bottom line.

- Videos: Watch demonstrations of our equipment and listen to testimonials from our customers and see how it can be used in your industry.

- Articles: Read articles about the latest trends in printing and converting, along with tips for improving your business.

We encourage you to explore our knowledge hub and learn more about how Matik can help your business succeed.

Stencilease.com

Stencil Ease of Old Saybrook, Conn., has purchased a Paperone 3500, an advanced sheetfed laser cutting system manufactured by SEI Laser. The Paperone 3500 will help Stencil Ease regain a competitive edge by providing ultrafast, precision, true digital finishing for small to large projects on demand. Sold and serviced by North American distributor Matik, Inc., the SEI Laser will help Stencil Ease open new, profitable markets for orders that were being manufactured in China.

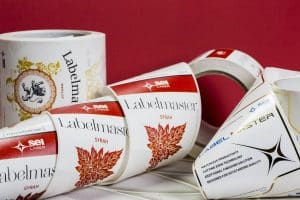

Enterprise Print Group Case Study

Enterprise Print Group invested in a SEI Laser Labelmaster to improve its efficiency and profitability. The Labelmaster has helped the company to reduce waste, improve productivity, and increase value for its customers. To learn more about how the Labelmaster is helping Enterprise Print Group, read the case study.

SEI Laser’s Mercury Fiber Reduces Production Time of Custom Electric Motors at VMF

VMF is a manufacturing company based in Paullo in East Milan. Founded in 1987, VMF is a specialist in cutting magnets for producing electric motors. Along with providing its customers with superior added value, it offers standard and custom motor production. “When it comes to the production of customized motors, we provide customers with end-to-end manufacturing services, including design to prototyping, from pre- to full production,” explains Fabio Menini, VMF’s sales manager.

Labelin Case Study

Labelin, a label printing company based in Irvine, California, has achieved order-to-ship automation of custom labels with the help of an SEI Laser Labelmaster. The Labelmaster has helped Labelin to reduce lead times, increase profit potential, and accommodate new niches. To learn more about how the Labelmaster can benefit your business, read the article.

TLF Graphics Case Study

Founded in 1980 and headquartered in Rochester, NY, TLF Graphics is a technologically diverse printing company specializing in product decorating for the food, beverage, cannabis, health and beauty markets. Providing short to medium runs and ecommerce ordering, the company’s mission is to deliver exceptional speed and service. To support their mission and better serve customers, TLF invested in an SEI Laser Labelmaster from North American distributor Matik, Inc.

Repacorp, Inc.

Repacorp Quality Labels and Packaging invested in a Labelmaster from SEI Laser to improve their efficiency and reliability. The Labelmaster is a high-speed, roll-to-roll and roll-to-sheet laser system that can process a variety of materials. Read the article to learn more about how the Labelmaster is helping Repacorp to improve their business.

The Future of Flexible Packaging

Buyers today expect more than just nice printing. Lasers are the key technology for the production of smart packaging — giving producers and consumers added value. Laser scoring, easy-opening packaging and laser perforated monolayer films can help enhance shelf life of perishable fresh food and are already widely used in the food industry. Laser-optimized packaging is simply better.

Easy Open Application in Flexible Packaging: Bags & Sacks

Laser scoring of flexible films is a non-contact, clean processing solution that eliminates the need for mechanical tooling or consumables. A fully digital workflow markedly reduces production downtime, as pattern or design modifications can be made instantaneously.

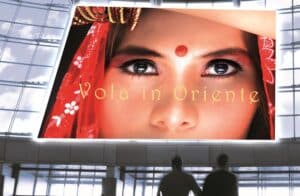

Expanding the Wide-Format Opportunity

Cutting technologies have become essential to wide-format production, and systems that don’t become production bottlenecks possess the strongest ingredient for success. Laser-enabled cutting systems can cut faster, in more shapes, and add embellishments to production that a knife-based cutters just can’t do.

True Digital Label Finishing: Increased Productivity, Capabilities and Profits

True digital label finishing uses high-speed lasers to cut and finish labels. This can significantly improve efficiency and profitability for label printers, as it eliminates the need for dies and other tooling. Learn more about how true digital label finishing can benefit your business.

Easy Open Application in Flexible Packaging: Snack N’ Seal

What is great about this new packaging is the resealable top designed to help keep the cookiesfresh. The design is called “snack n’ seal” and that’s amazing. Learn about techniques and laser systems that can help you gain a competitive edge, increase productivity and reduce production costs. Gain insight into how you can achieve unique easy-open snack n’ seal packaging solutions.

A Window to Better Packaging

There has been a rapid increase in demand for customer-friendly packaging and enhanced product protection. Beyond visibility, consumer lifestyle trends, convenience and portability of products, make flexible packaging an attractive choice for brand owners. Learn how laser technology is leading this trend.