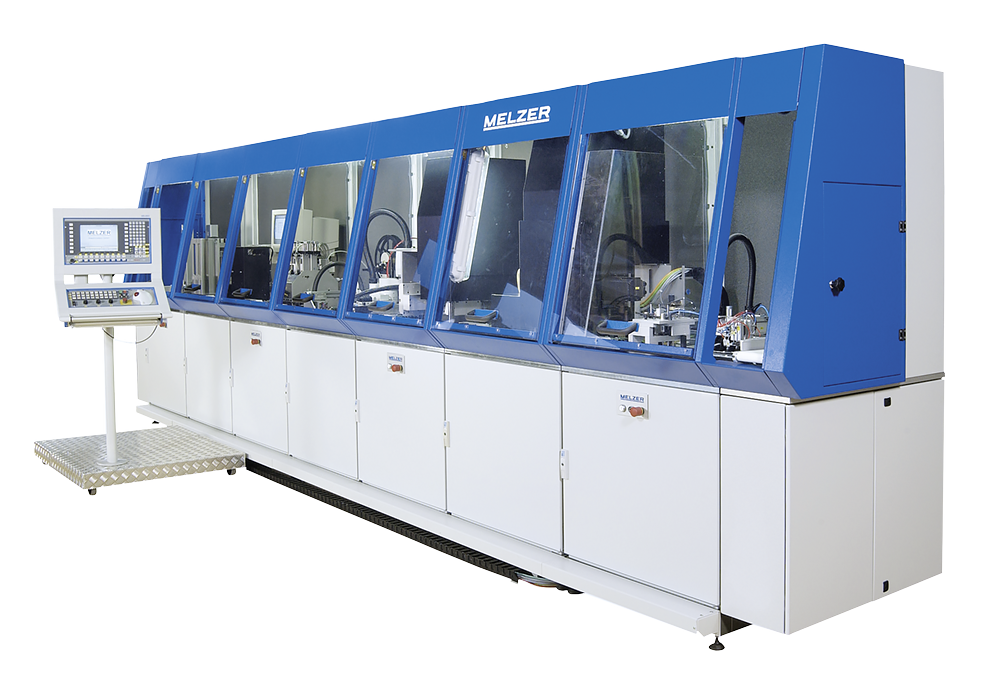

This high speed machine, combining milling and implanting, belongs in the class of the fastest and most powerful in the industrial production of chip cards.

This high speed machine, combining milling and implanting, belongs in the class of the fastest and most powerful in the industrial production of chip cards.

Milling of the cavity and implanting of the chip module with an output of up to 5,500 cards/h is carried out in one line, working from magazine to magazine.

Even the fully automatic magazine change does not affect the high machine output – card buffers feed the line with cards during the magazine change and ensure the continuous production of highly accurate chip cards.

The simultaneous processing of 4 cards allows longer cycle times and ensures a trouble-free card transport, more precise positioning and an optimum dwell time in the lamination station (heating/cooling). First-class components and industrial robot technology insure reliable functions in a 3-shift operation.

The MI-5000 is a modular design and consists of 6 basic modules and 2 magazine modules. An upgrade to dual interface card production can be done on site or at any time.

Quick Links