The MELZER M4-S Machine opens a new dimension in manufacturing sheet-based products. The fully digital production machine makes production on demand become reality.

Designing, programming and manufacturing of products on one machine guarantees the essential flexibility needed today – the modular M4 concept is designed for future production requirements.

Designing, programming and manufacturing of products on one machine guarantees the essential flexibility needed today – the modular M4 concept is designed for future production requirements.

Fast and highly precise drives ensure that even tightest product tolerances are being met. Up to 8 identical tools can be installed on the MELZER M4-S for maximum performance or up to 8 different tools for production of extremely sophisticated products at one shot. The large working area allows simultaneous production on 2 sheets or more while customized alignment systems for sheet positioning eliminate sheet-to-sheet variations.

Change-over times for tools are less than one minute and the machine automatically detects the type of tools installed. Loading a new program into the PLC just takes seconds. Saving, modifying or creating new files can be done on the machine during production or at a remote location via network connection. Minimum setting times, lowest waste and fastest job changes make this machine very productive and highly efficient.

Technical Data M4-S Machine

| Maximum sheet size: | 55 x 63 in (1,400 x 1,600 mm) |

|---|---|

| Maximum processing format: | 35 x 35 in (900 x 900 mm) |

| Material thickness: | 0.002 to 0.08 in (0.05 to 2 mm) |

| Maximum speed: | 30 m/min |

| Machine logic control: | PLC system with keypad and display |

| Programming system: | Industrial PC system |

| Power supply: | 3 x 400 V, 50 Hz, NPE |

| Dimensions (L x W x H): | 90.5 x 70.8 x 67 in (2,300 x 1,800 x 1,700 mm) |

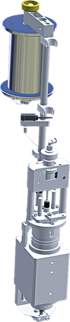

Wire-Embedding Tool

The new MELZER M4 system creates a new world of manufacturing possibilities – the innovative world of digital manufacturing equipment.

With this M4 system a new range of production machines for sheet and reel-to-reel production is being introduced. Wire embedding, pick & place, bonding, dispensing, checking, die-cutting, punching and laser cutting can be done on one machine – fully digital. No expensive tooling costs and no lead times for tooling. Production on demand with highest flexibility.

Quick Links