WEST HARTFORD, Conn.— Carlisle Construction Materials, located in Carlisle, Pa., had for many years been looking for a solution to minimize fiberglass dust dispersed into the air during manufacturing of its Water and Ice Protection (WIP®) 100 self-adhesive shingle underlayment. The Kelva noncontact web cleaning system, distributed in North America by Matik, Inc., delivered. It vacuums up the particles before being dispersed into the air.

WIP 100 is used for critical roof areas such as eaves, dormers and skylights. It protects roof structures and interior spaces from water penetration caused by wind-driven rain and ice dams. The underlayment is constructed of a reinforcement fiberglass roll material that is submerged in rubberized asphalt, topped with nonskid granules and backed with a silicone-treated release liner.

During manufacturing, the fiberglass sheeting is unwound, breaking the fiber strands, and releasing particles into the air. These dust particles caused itchy discomfort for employees and collected on the equipment and the floor.

“While the workers built up a tolerance to the dust, we received complaints,” says Tim Patchett, plant manager at Carlisle Construction Materials. “You could see the fiberglass dust sparkling in the air. At the end of every shift the guys would wipe down the equipment and sweep the manufacturing area. They filled a five-gallon bucket with the dust after every shift. We worked for years to find a solution.”

A colleague of Patchett’s at another Carlisle plant that produces a fiberglass-faced paper identified Kelva’s cleaning systems as a potential solution for their application. To assess the Kelva noncontact web cleaning system for WIP 100 manufacturing, Patchett met with representatives from Kelva and Matik at a manufacturer in Pennsylvania that was using the system.

“We were able to see the Kelva system in action and get firsthand feedback on its performance,” says Patchett. “They were incredibly happy with the Kelva cleaning system. That sealed the deal. Later we learned that the supplier of the fiberglass material in WIP also uses the Kelva noncontact web cleaning system.”

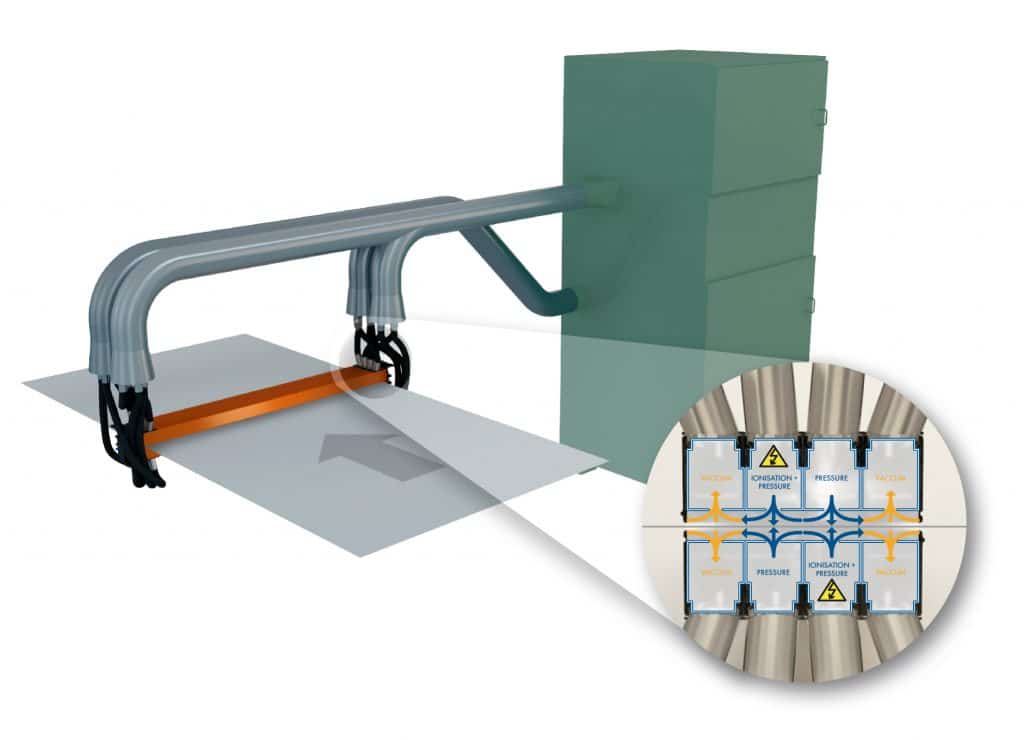

Kelva coordinated with Matik, Inc., its North American distributor. The technical engineers at Kelva and Matik determined how many Kelva noncontact cleaning heads would be needed to successfully minimize the fiberglass particles. They also provided drawings with identified components for installation. The proposed system included heavy-duty round metal duct work as well as a collection and filtration cabinet mounted six feet higher than traditional Kelva installations. That allowed the dust to be collected in repurposed sacks that originally contain raw material for manufacturing the product. The collection cabinet, which also contains an electronic pulse system to keep the filters clean, was mounted on a steel frame with custom brackets built in-house in Carlisle.

Installation went as planned, and there were no cost overruns. Carlisle’s maintenance team and in-house electrician completed most of the installation of the Kelva noncontact web cleaning system. Kelva and Matik visited during the facility’s annual shutdown to check the installation, start the system and provide training.

“It was a pleasure to work with Matik and Kelva,” explains Patchett. “Eliminating excessive dust improved the product quality. And I have heard nothing but good feedback from the operators. They are done being itchy, which helps us retain and attract new workers. Our employees’ health and safety made the investment completely worthwhile.”

Kelva noncontact web cleaning system incorporates cleaner heads, antistatic equipment, a filter/fan unit and dust collection system. Several models are available for a wide range of continuous-running substrates in widths from 11.81” (300 mm) to 32.8’ (10 m). Compact for integration in nearly any application, Kelva offers cleaning solutions for a range of substrates including, fiberglass sheeting, tissue, corrugated, glass, laminating, newsprint and many more. To see a video showing how the Kelva noncontact web cleaning system works, visit www.matik.com/products/kelva-web-cleaning-systems/ or call 860-232-2323.

About Kelva

Founded in Sweden in 1970 as a branch of the Åkerlund & Rausing packaging company, Kelva offered air-operated solutions for web tension, pumping of liquids and level measurements for explosion-hazardous environments, being a pioneer in the ATEX field. In 1982 Kelva introduced the first noncontact web cleaner at DRUPA and has been an industry leader in sheet and web cleaning ever since. With over 6,000 installations worldwide, Kelva is the leading supplier of web and sheet cleaning solutions. Kelva designs and manufactures, contact and noncontact web cleaning solutions for newsprint, corrugated board, tissue, nonwoven, film, glass, label print and others.

About Matik, Inc.

Matik, Inc. is the North American distributor of Kelva and other premier European technologies. With headquarters in West Hartford, Connecticut, and several regional sales and service offices, Matik offers the widest range of printing, converting and packaging equipment in the industry. For over 40 years Matik has delivered innovative technologies and dependable customer support. matik.com