Features:

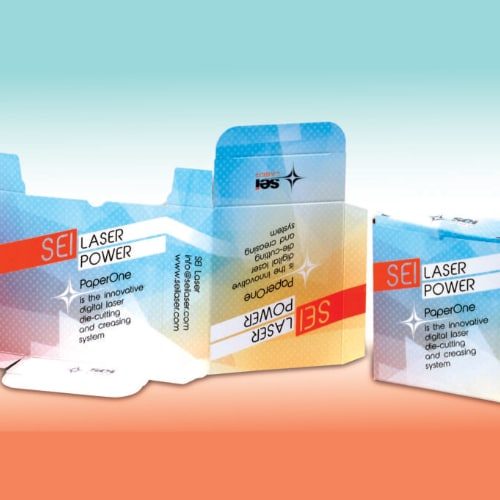

X-Wave Converting offers numerous unique advantages in corrugated production processes in just one system.

X-Wave Converting is a modular production line, consisting of the following process stations: loading, visioning, digital creasing, laser cutting and unloading, each equipped with specific conveyors.

The entire machining process is automated without any interruption or pause, thanks to the sophisticated engineering from SEI Laser, which keeps the conveyors synchronized.

The transport speed of the material is optimized according to the maximum speeds of each single process.

Equipped with a high-resolution vision scanner, this system uses innovative optical sensors to ensure perfect registration for creasing, laser cutting while achieving consistent results with printed materials.

Features:

X-Wave Converting offers numerous unique advantages in corrugated production processes in just one system.